Save money with the bubble-tight Soft Seated Valve Design

Besides to the well-known hard seated valves Soft Seated Valves are considered to be bubble-tight and leak-free. Bubble-tight shut off is required to achieve accurate measurement through the use of instrumentation valves and manifolds.

The Challenge

Achieving this leak free shut off on valves used in industrial applications is sometimes a challenge. The challenge is due to the service or media in contact with the valve/manifold. Media can be gas, vapor, liquid, steam or a combination of all. The requirement of a soft seat is to provide optimum bubbletight shut off and repeatable bubble-tight performance.

In the case of natural gas where the media is corrosive and debris is common eventually causing the best of valves to begin leaking the ability to replace the seat(s) is necessary. By changing the seats a bubble-tight leak free installation is again achieved. The need to purchase a new valve or manifold is not necessary saving users operating and maintenance costs.

The Solution

The 3/8″ (9.5 mm) Bore Size provides a larger internal flow path which helps to reduce freezing and plugging issues. The “Joule-Thomson” effect* is also reduced in many gas applications.

Comparison of Soft Seated Valve Options

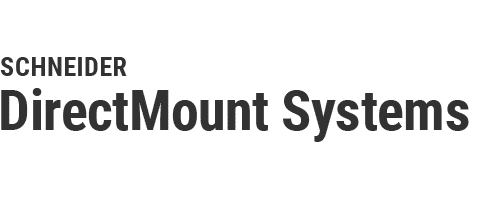

Soft Seat – Cone Design

Bore Size 1/4″ (6.35 mm) and 3/8″ (9.5 mm)

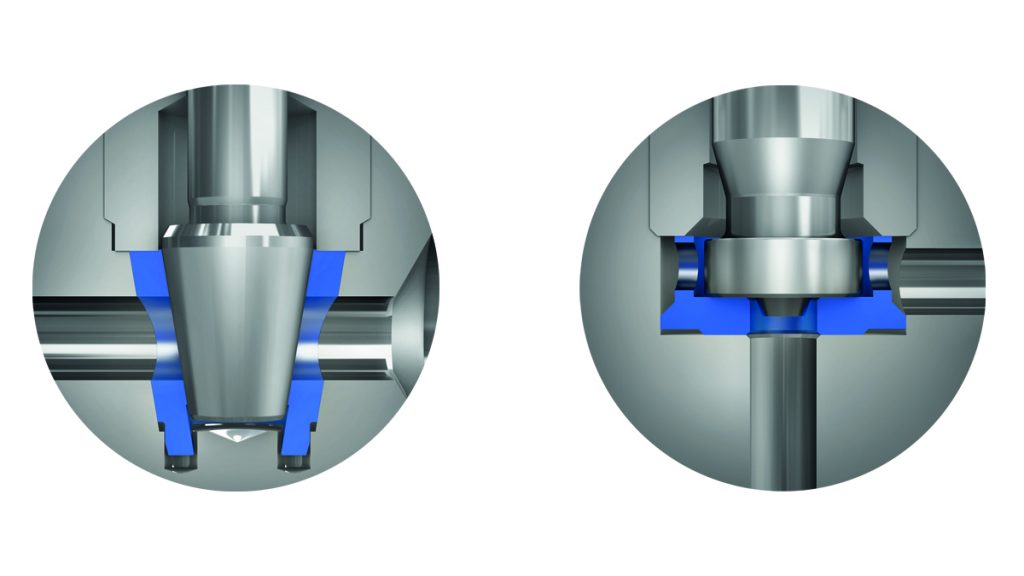

Soft Seat – Cup Design

Straight-Through Design => Fully Roddable for

easy cleaning if used in dirty service

* In thermodynamics, the Joule-Thomson effect describes the temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the environment.

(Image source: © pipicato / Fotolia)