Direct Mount Systems

Benefits for different Direct Mount Application Fields.

Benefits Overview

Be inspired of the comprehensive benefits of a DirectMount System. Soft goods available to meet the toughest dirty gas applications. H2S, CO2, amines, corrosion inhibitors, methanol, glycol etc.!

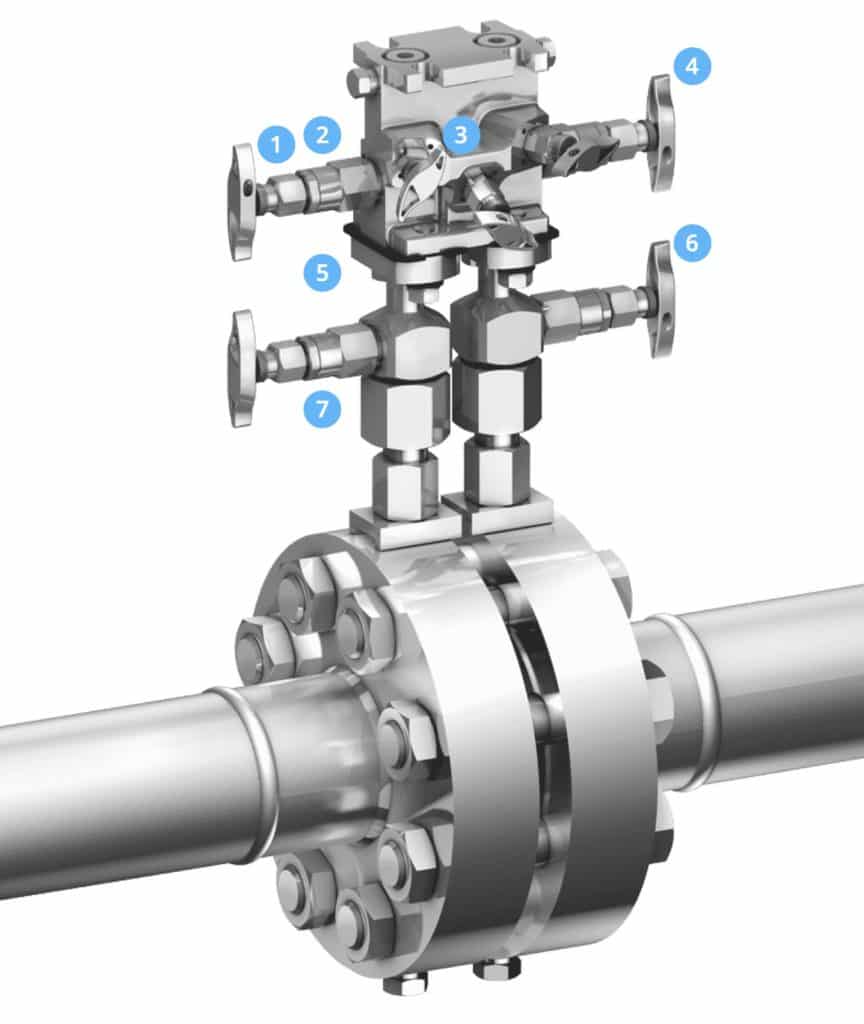

1

2

3

4

5

6

7

1. Stem Design

Reduced operating torque.

Minimized gap between stem and stem nut for additional operating thread protection.

2. Cost Savings

Extended seal and packing life.

3. Reduces Freezing Issues

Flow paths machined to self drain condensates and liquid accumulation.

4. Protection and Convenience

6 1/2 turns to full open & close isolation valves. Protects electronics from pressure spikes.

5. Cathodic Protection

Dielectric isolators protect expensive electronics.

6. Comfortable Easy Turn

Ergonomic handle design

7. Safety

Ships assembled & pressure tested. No seat and bonnet field assembly required.

Benefits for different

Direct Mount

Application Fields

Purchase & Supply Chain

- Total Costs of Ownership (TCO/TVO): Base your purchase decision on TCO/TVO calculations rather than simply lowest costs (e.g. extended seal and packing life) Mount Applications.

- Approved Vendor List (AVL): Access to valuable information to base your selection of vendors.

- Ships assembled & pressure tested: No seat and bonnet field assembly required.

- Patented Technology: Stay updated about latest developments with our blog regarding Direct Mount Applications.

Piping and Design Engineering

- Quality Products: We understand your focus on getting best quality products installed on your pipelines that`s why our Direct Mount Systems are exposed to extremely high stresses.

- Reduced Operating Torque: Minimized gap between stem and stem nut for additional operating thread protection. 6 1/2 turns to full open & close isolation valves.

- Reduces Freezing Issues: Flow paths machined to self drain condensates and liquid accumulation.

- Ships assembled & pressure tested: No seat and bonnet field assembly required.

- Cathodic Protection: Dielectric isolators protect expensive electronics.

- Free 3D Models: Make your life easier with free access to 2D model and 3D model drawings.

- Technical Documentation: Provide from the free access to technical documentation and datasheets.

- Standards: Get regularly updates about standards and regulations for Direct Mount Applications.

- Patented Technology: Stay updated about latest developments with our blog regarding Direct Mount Applications.

Maintenance

- Easy Maintaining and Handling: We know the pain of maintaining and handling bulky products on the field. Stay informed about latest trends and information making your life easier.

- Comfortable Easy Turn: Ergonomic handle design and reduced operating torque help to prevent carpal tunnel syndrome at field operators. Only 6 1/2 turns to full open & close isolation valves.

- Protection and Convenience: Protects electronics from pressure spikes. Ships assembled & pressure tested: No seat and bonnet field assembly required.

- Space and Weight: Reduced weight and space in case when you have to climb up the tower to change the Direct Mount Systems.

- Customer Service: We offer you a reliable spare parts service for Direct Mount Systems and an easy communication with a local hotline and physical support.

Occupational health and safety

- Complies with the Occupational Health and Safety Standards: Safety requirements in the process industry are extremely high. In some plants, especially in processes, involving flammable liquids or toxic gases, such a leakage can lead to risks to the plant but much important to the personnel. Isspecially for engieers with focus on maintenance and facility.

- Ships assembled & pressure tested: No seat and bonnet field assembly required.

Environment

- Limiting Fugitive Emissions: Keep in mind that stringent legal requirements force certain industries to track and limit Fugitive Emissions by using emission-reducing equipment.

- Environmental Regulations: We regularly povide our customers with updates about environmental standards and regulations such as TA-Luft or ISO 15848.

- Direct Mount System: We recommend facility engieers to use Direct Mount Systems with special sealing technology which is type tested by ISO 15848 standard.