Useful little helpers in the measurement of natural gas

Field research and testing conducted by Southwest Research in San Antonio, Texas and the Pipeline Gas Compressor Research Council (PCRC) confirmed that pulsation created by compressors, flow control valves, regulators and some piping configurations may create undesirable levels of Square Root Error (SRE) and/or resulting Gauge Line Error (GLE). Pulsation at the orifice meter is a major source of lost and unaccounted for natural gas. These errors create either large economic gains or losses for the buyer and seller along a natural gas pipeline system.

Safe money with accurate measure results

For more accurate natural gas measurement, electronic differential pressure devices are used. Between the orifice and the transmitters various shut-off valves are used. They allow a maintenance and calibration. When mounting often, however, there are enormous space problems. Many suppliers supply the valve unit in individual pieces, which can only be assembled on site under rough conditions. The disadvantage: The difficult conditions can lead to incorrect assembly and thus to leaks.

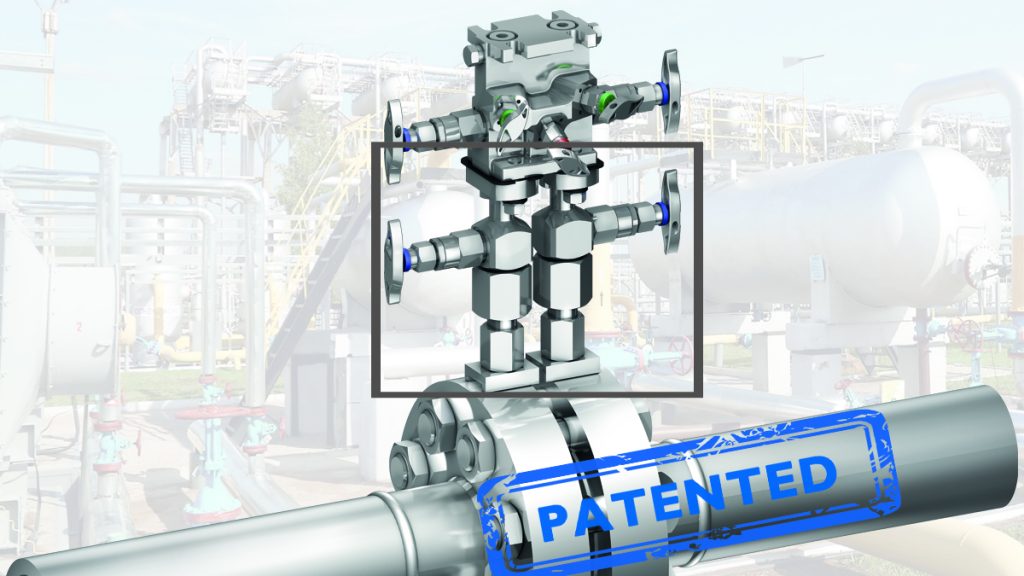

This is exactly where I can recommend the use of Schneider DirectMount Systems (SDMS). Unlike traditional systems, users do not need to install tube runs, fittings, and expensive pipe stands. Instead, you successively assemble two stabilized connectors.

If the stabilized connectors are assembled, you can easily assemble the second part with a nut to the valve, without rotating it. This greatly simplifies assembling. In addition, the system reduces potential leak points as the SDMS are delivered pre-assembled.

How are the Schneider DirectMount Systems structured?

The SDMS are available as a vertical and horizontal installation. The heart of the system is the above mentioned patented stabilized connector with integrated shut-off valve. In order to be able to connect the manifold to the measuring orifice flange, a special adapter is necessary. This adapter is supported on the body of the measuring orifice flange which provides for more stability. The entire structure with the 5 valve manifold and transmitter or flow computer has, however, a high net weight. In addition, vibrations from the pipeline can affect this connection so that this thread is often damaged or destroyed. With the stabilized connector, this risk has been minimized. The patented system is thus much more protected and allows a professional and simple assembly even in harsh conditions. The user thus receives a safe, compact and leak free measurement installation.

(Image source: © Shutterstock (image no. 45253774) & AS-Schneider)