Stabilized Connectors for DirectMount Systems

Conventional Installation with impulse piping

To overcome the disadvantages of a remote mount installation a DirectMount System is a premier choice. All needed components for such applications are supplied, providing a minimum of installation costs and leading to an easy, safe and efficient method to connect Electronic Flow Measurement Devices resp. Transmitters to an orifice meter.

The DirectMount System could be used in various industries; however today it’s mainly used in the Natural Gas Industry.

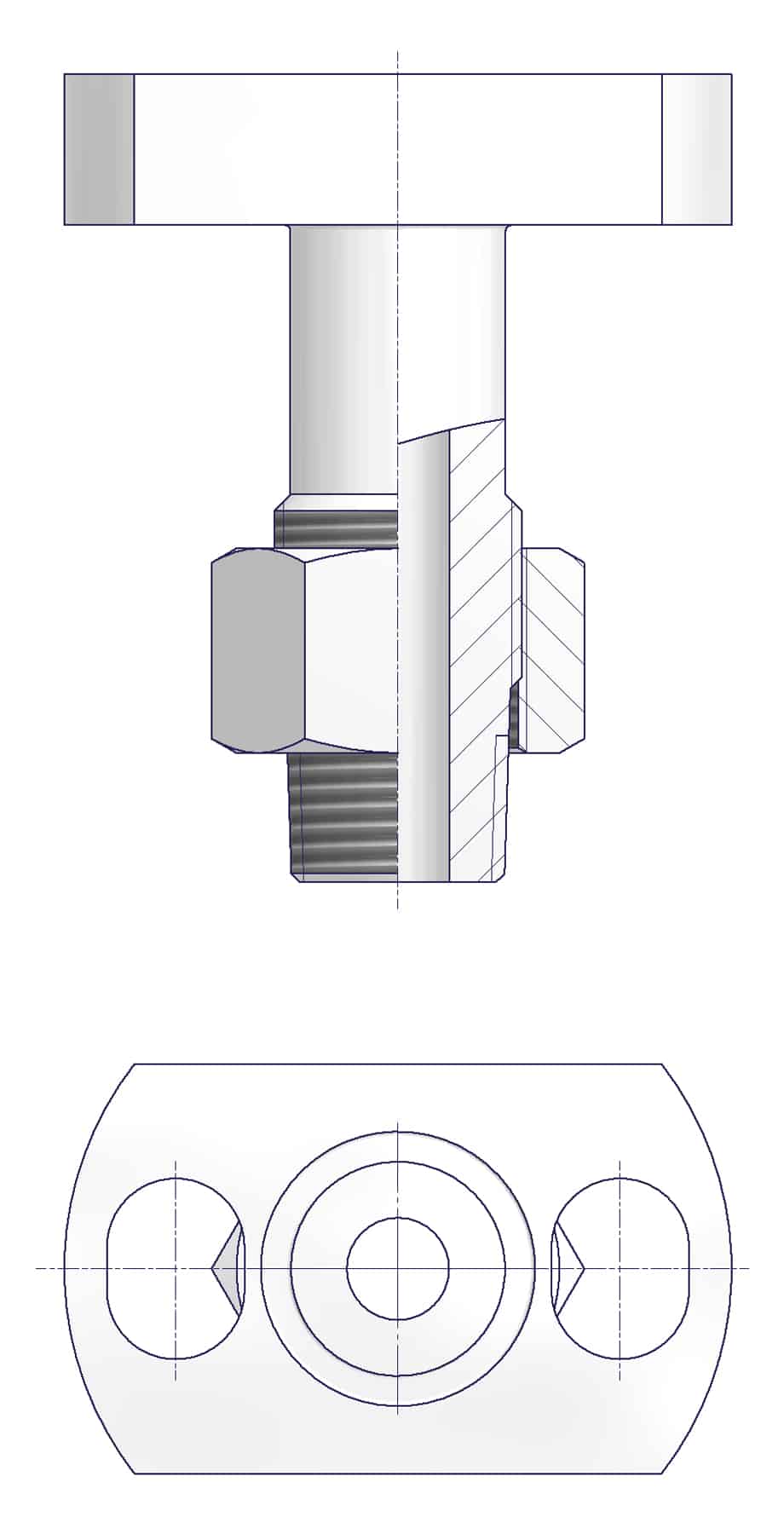

The basic components of a DirectMount System are Stabilized Connectors, Dielectric Isolation Kits and Manifolds. Stabilized Connectors are directly installed onto the orifice meter or orifice fitting by a 1/2 NPT connection. In order to get a rigid installation, the connector’s tensioning nut places the NPT threads in tension and transfers radial forces away from the NPT threads. Vibrations on the close coupled hook-up are thereby reduced and therefore additional components like adapter plates can be installed.

These close coupled installations can easily be configured and used for vertical and also horizontal applications. In both cases Stabilized Connectors are essential for having a rigid installation.

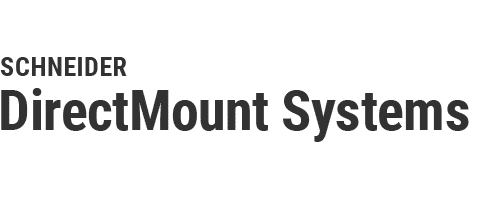

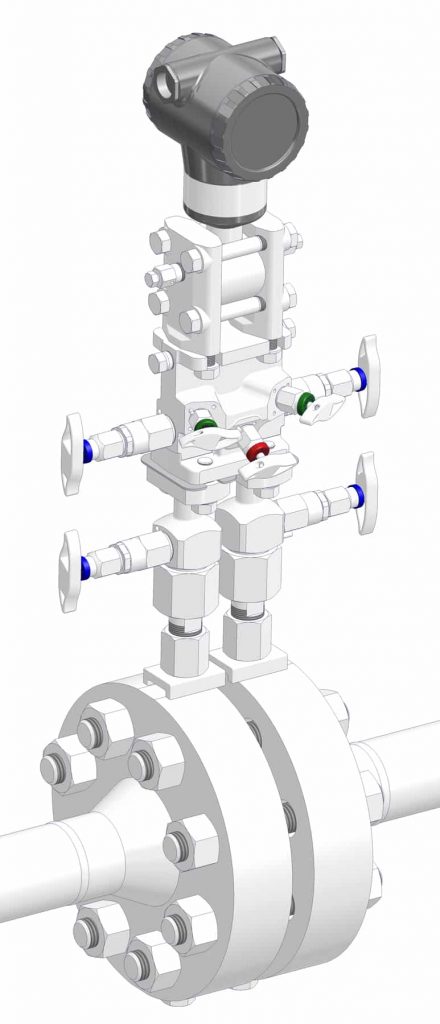

DirectMount System

Vertical Installation

Horizontal Installation

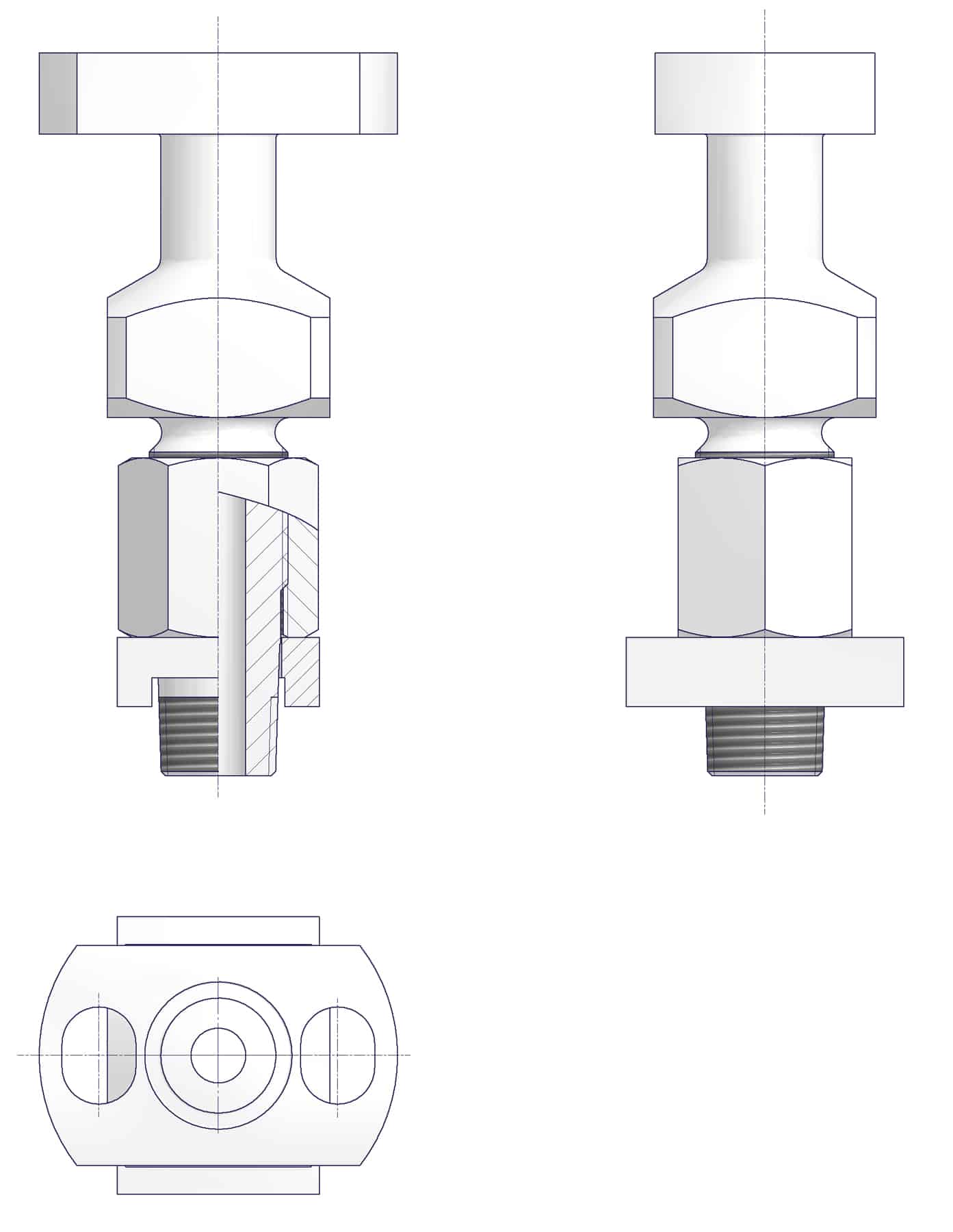

Stabilized connectors are available in 3 basic designs:

Short type

Short Type Stabilized Connector for Standard applications, to be installed without shoe

Long type

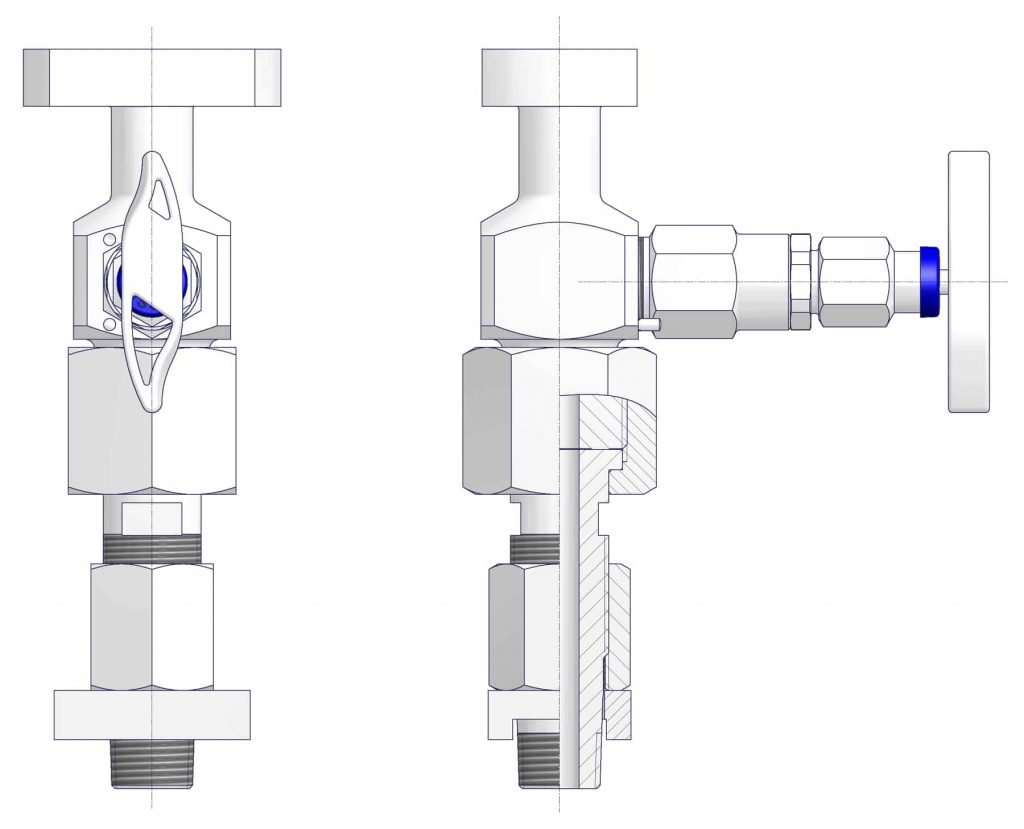

Integral Valve Type

Short Type Stabilized Connector for Standard applications, to be installed without shoe

The Stabilized Connector design allows an installation to the two NPT threaded orifice taps with a center-to-center distance of 2 1/8″ (54 mm) up to 2 1/4″ (57 mm). The slotted holes in the flanges can compensate any inaccuracy of the orifice taps. Long Type and Integral Valve Type are designed to be installed with shoe, providing a very solid and efficient connection. The Integral Valve Type is equipped with a swivel adapter enabling the easy positioning of the valve head unit in any direction through 360° (Patent Pending).

In order to protect expensive electronics, dielectric isolators are often required for cathodic protection. Therefore Dielectric Isolation Kits are optional available. These kits are mounted between the Stabilized Connector and the manifold to ensure electric decoupling between the process line and the Transmitter / Electronic Flow Measurement (EFM) device.

Stabilized connectors are part of DirectMount Systems and one of the most important components of this close coupled hook-up. Using large bore components (0.375″ I.D. or greater), this close coupled hook-up reduces the effects of Gauge Line Error, reduces potential leak points, reduces freezing and plugging issues and provides a safe compact leak free installation.

Summary

Stabilized Connectors are essential when using a DirectMount System and are therefore the key for an easy, safe and efficient method to connect EFM’s and transmitters to an orifice meter / orifice fitting.