Small, but powerful: Low torque for a smooth operation

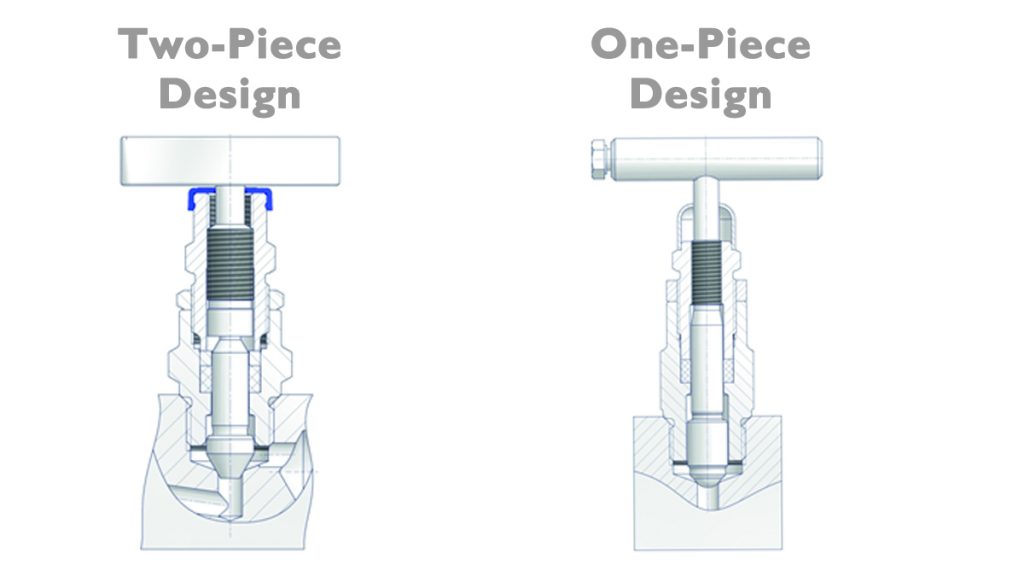

During my last 12 years in the instrumentation business I get asked at which pressure is a manifold useable and still turnable? As well as, what is the difference between a One-Piece Design and a Two-Piece Design Stem?

Let me explain the difference:

The interface of stem and needle is above the packing. This means: The needle is conducting an up-and-down movement only. When opening / closing the valve, any spot on the needle covers a distance of 4 mm.

Typical valve stem designs are covering a much longer distance (94 mm), if we are calculating with the same dimensions (stem Ø 7.5 mm x π x 4 mm stroke). This difference of 4 mm to 94 mm is resulting in a smooth operation and minimum wear of sealing elements and results in a long service life. Basically: Made for smooth operation!

The biggest benefit of the Two-Piece Design is the easy way in terms of the torque for operating. It doesn’t matter which pressure is given. Easy operating with 2 bar or up to 689 bar.

Björn Bofiner

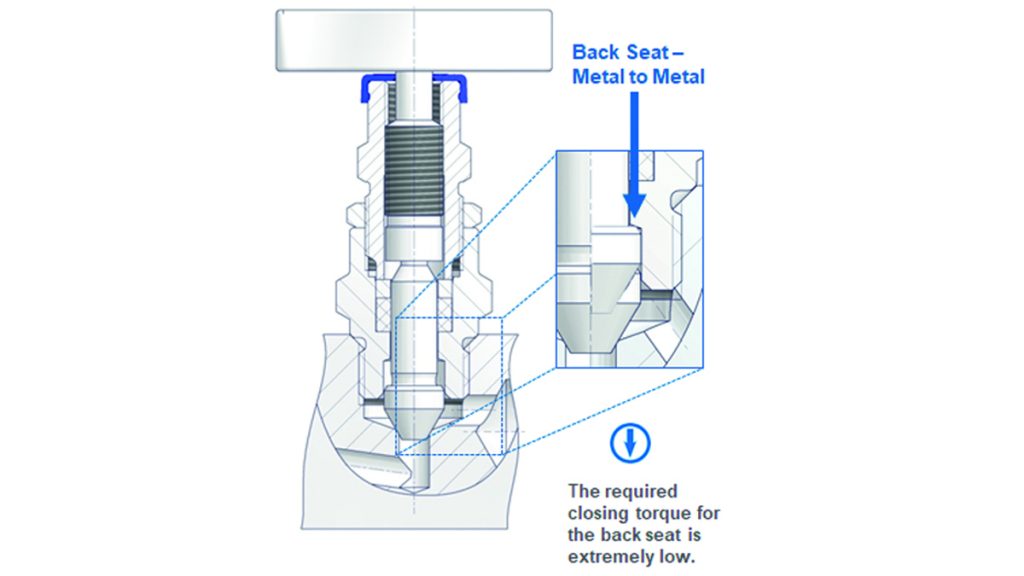

Why is it important to use a back seat?

Some manufactures are waiving the back seat, this is a safety issue!

Using the back seat means releasing the packing stress. Without back seat the packing will be permanently under pressure if the valve is open (this does always apply to Equalizer Valves).

Using the back seat design, the packing is only under pressure during the few seconds the valve is operated (either closed or opened). This is tremendously increasing the lifespan of the packing itself. The Fugitive Emission rates are reduced to a minimum (metal to metal back seat).

In case of packing failure, there won`t be any leakage if the valve is closed against the back seat.

(Image source: © imhof79ch/Fotolia & AS-Schneider)